Description of the Products

Areas of Application

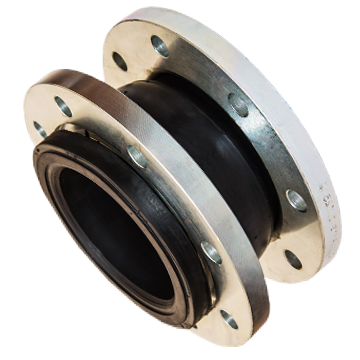

Rubber expansion joints are the movable parts of pipeline systems which are smoothing out their thermal elongations, oscillations or vibrations in all directions. The rubber expansion joints are considered to be one of the most critical structural elements of pipelines used for transporting liquid media. Such pipelines are experiencing changes in pipe lengths due to variable temperatures, vibrations from operating pumps and ripples from technical installations, all of which can be suppressed and dampened by these rubber expansion joints.

Typical places for installing the rubber expansion joints are pumps, water supply pipelines, transporting lines for crude oil and petroleum, as well as for the aggressive liquid media (for instance, acids).

Design of the Rubber Expansion Joints

Rubber expansion joints are made of the flexible corrugated elastomers and come with flanges of carbon or stainless steel intended for fastening to a pipe. Our know-how in the area of elastomeric materials allows us to produce high-quality rubber expansion joints for all kind of liquid media customarily used in industry and during construction of industrial facilities.

For water and non-aggressive media we use the best of the EPDM (ethylene-propylene-diene monomer rubber) elastomers supplied by the leading manufacturers. For the fluids containing petroleum products, we use our professional knowledge of the NBR (nitrile butadiene rubber) elastomers. During the fabrication of rubber expansion joints, we vulcanize this material to obtain higher values of tensile strength, stretching and resilience to the effects of temperatures and corrosive properties of the medium.

When it comes to handling very aggressive media, we offer rubber expansion joints made from the organofluoric rubber. By implementing a layer of PTFE (polytetrafluoroethylene) we improve the resilience of rubber expansion joints and enhance their operational reliability.